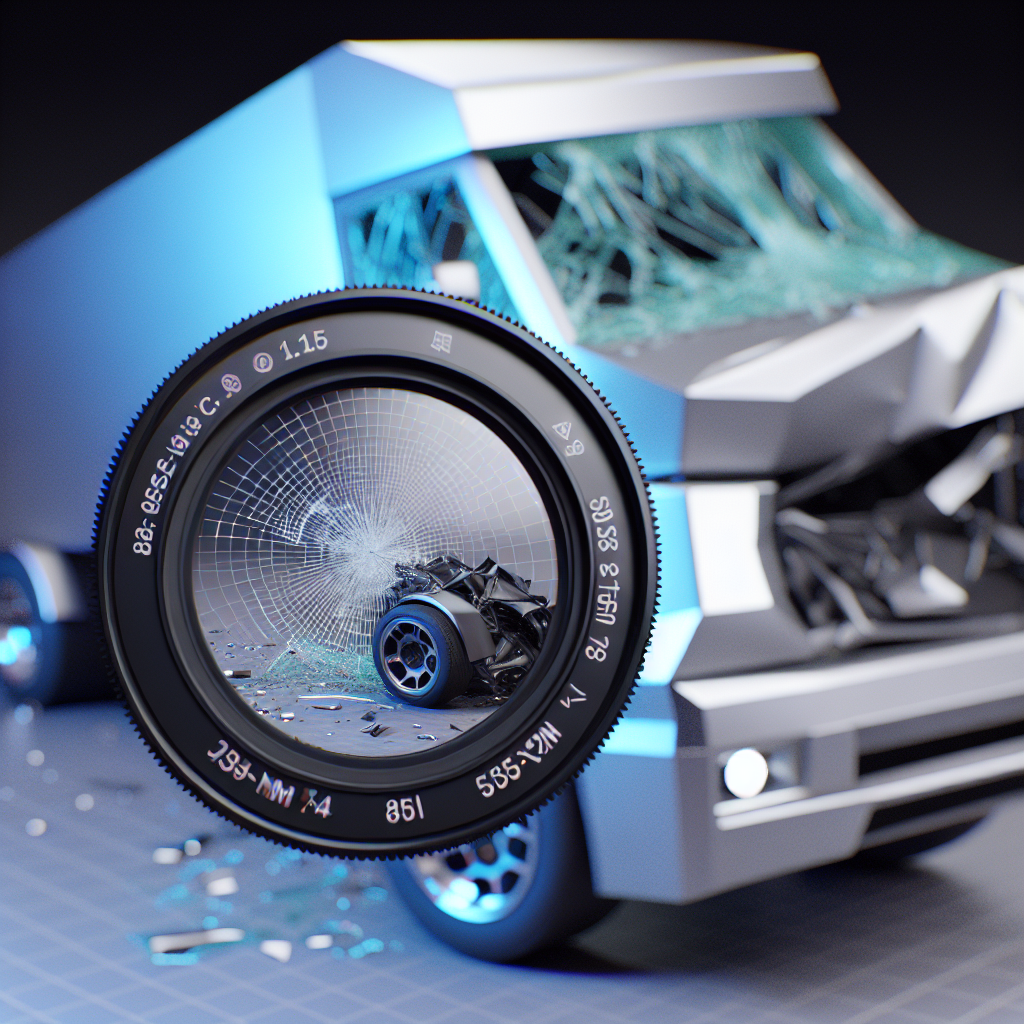

Recent advancements in vehicle safety are often showcased through simulated crash tests, and the Tesla Cybertruck has become a focal point due to its innovative design and expected durability. In this article, we delve into a popular BeamNG.Drive crash test video of the Cybertruck, analyzing its performance, safety features, and what it signifies for future automotive safety standards.

Simulating the Unthinkable: Cybertruck Crash in BeamNG.Drive

The BeamNG.Drive crash test video provides a virtual simulation of the Tesla Cybertruck undergoing a high-impact collision. Unlike traditional crash tests performed in specialized laboratories, BeamNG.Drive offers realistic physics-based environments that allow enthusiasts and engineers to evaluate vehicle safety in a controlled, cost-effective manner. The Cybertruck’s design, characterized by its angular panels and stainless steel exoskeleton, was put to the test to gauge how it withstands severe impacts.

Key aspects analyzed in the simulation include:

- Structural integrity: The robust exoskeleton’s ability to absorb and dissipate crash energy

- Passenger safety zones: How the cabin maintains its shape and protects occupants during impact

- Crash dynamics: The impact behavior of the vehicle upon collision, including deformation patterns and potential failure points

While virtual crash tests cannot replace real-world testing, they provide critical insights into the vehicle’s potential safety performance and highlight areas for improvement before mass production.

Implications of the Crash Test Results and Future Perspectives

The simulated crash results of the Tesla Cybertruck in BeamNG.Drive suggest a strong structural frame capable of handling high-impact forces, consistent with Tesla’s claims of durability and safety. The simulation underscores several important points:

- Design advantages: The Cybertruck’s angular, exoskeleton-heavy body structure distributes crash forces effectively, potentially enhancing occupant protection.

- Safety innovations: The use of stainless steel not only reduces weight but also improves crash resilience, a factor reflected in the simulation outcomes.

- Regulatory readiness: As virtual crash tests offer valuable early feedback, manufacturers like Tesla can refine their designs to meet or exceed safety standards, accelerating the development process.

Continued reliance on advanced simulation tools like BeamNG.Drive complements traditional crash testing, offering a comprehensive view of vehicle safety. While real-world crash tests remain essential, these virtual assessments foster innovation by enabling rapid iteration and testing of different design concepts before physical prototypes are built.

In conclusion, the BeamNG.Drive crash test of the Tesla Cybertruck sheds light on its promising safety features, emphasizing the importance of creative simulation tools in modern automotive development. As the Cybertruck moves closer to production, anticipated real-world crash tests will further validate these virtual findings, paving the way for safer, more durable electric vehicles in the future.