Designing efficient pumping stations is critical for ensuring seamless fluid management in various industries. Leveraging Building Information Modeling (BIM) enhances accuracy, coordination, and project delivery. This article explores how BIM revolutionizes pump station design, from conceptual planning to construction, unlocking new possibilities for plant solutions.

Transforming Pumping Station Design with BIM Technology

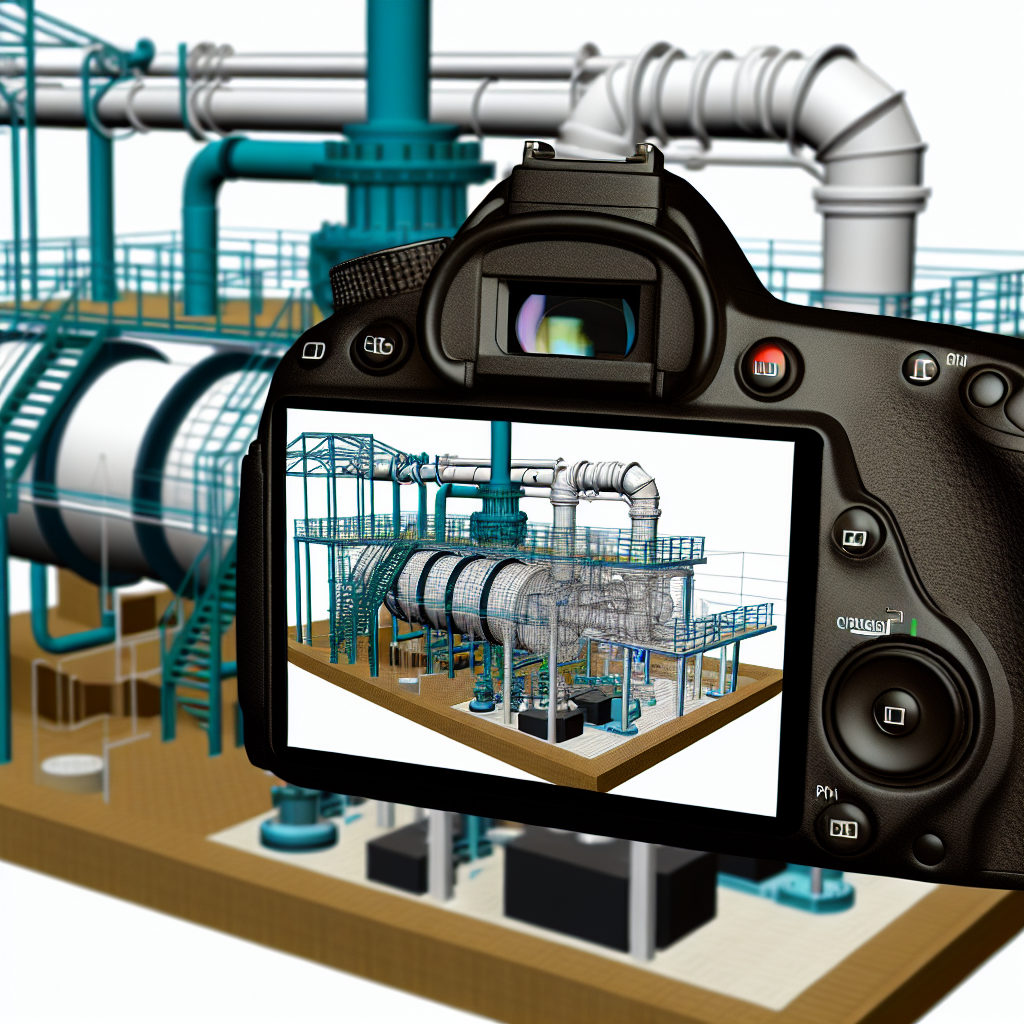

Building Information Modeling (BIM) has become an essential tool in modern infrastructure projects, especially in the design and construction of pumping stations. Unlike traditional 2D drawings, BIM offers a dynamic 3D model that integrates geometric and functional data, enabling engineers and designers to visualize every component in a unified platform. This integration facilitates better coordination among different disciplines such as civil, mechanical, electrical, and plumbing, reducing clashes and errors early in the design process.

In the context of pump station design, BIM allows for precise modeling of complex systems including pumps, valves, piping networks, electrical systems, and structural elements. This results in optimized layouts that improve operational efficiency and ease of maintenance. Additionally, BIM enables simulation of hydraulic performance, structural integrity, and energy consumption, ensuring that the station meets both performance and sustainability criteria. This proactive approach saves time and costs while enhancing project accuracy and stakeholder collaboration.

Key Benefits of Using BIM in Pump Station Projects

- Enhanced Visualization and Communication: Interactive 3D models make it easier for all stakeholders to understand project scope and design intent, fostering clearer communication and reducing misunderstandings.

- Clash Detection and Conflict Resolution: BIM software detects spatial conflicts between piping, electrical systems, and structural components early, preventing costly redesigns and delays during construction.

- Improved Project Coordination and Scheduling: Digital models serve as a basis for detailed scheduling and sequencing, ensuring smooth project progression from design to commissioning.

- Accurate Quantity Takeoffs and Cost Estimation: BIM allows precise calculation of materials and labor, leading to more accurate budgets and resource planning.

- Sustainable Design and Lifecycle Management: BIM integrates environmental data, emphasizing energy-efficient components and fostering better maintenance planning throughout the plant’s lifecycle.

Conclusion

Integrating BIM into pump station design significantly streamlines projects by enhancing visualization, promoting collaboration, and minimizing errors, leading to cost-effective and sustainable solutions. As the industry advances, adopting BIM is no longer optional but essential for delivering high-quality plant solutions efficiently and reliably. Embracing this technology paves the way for innovative infrastructure development in the future.