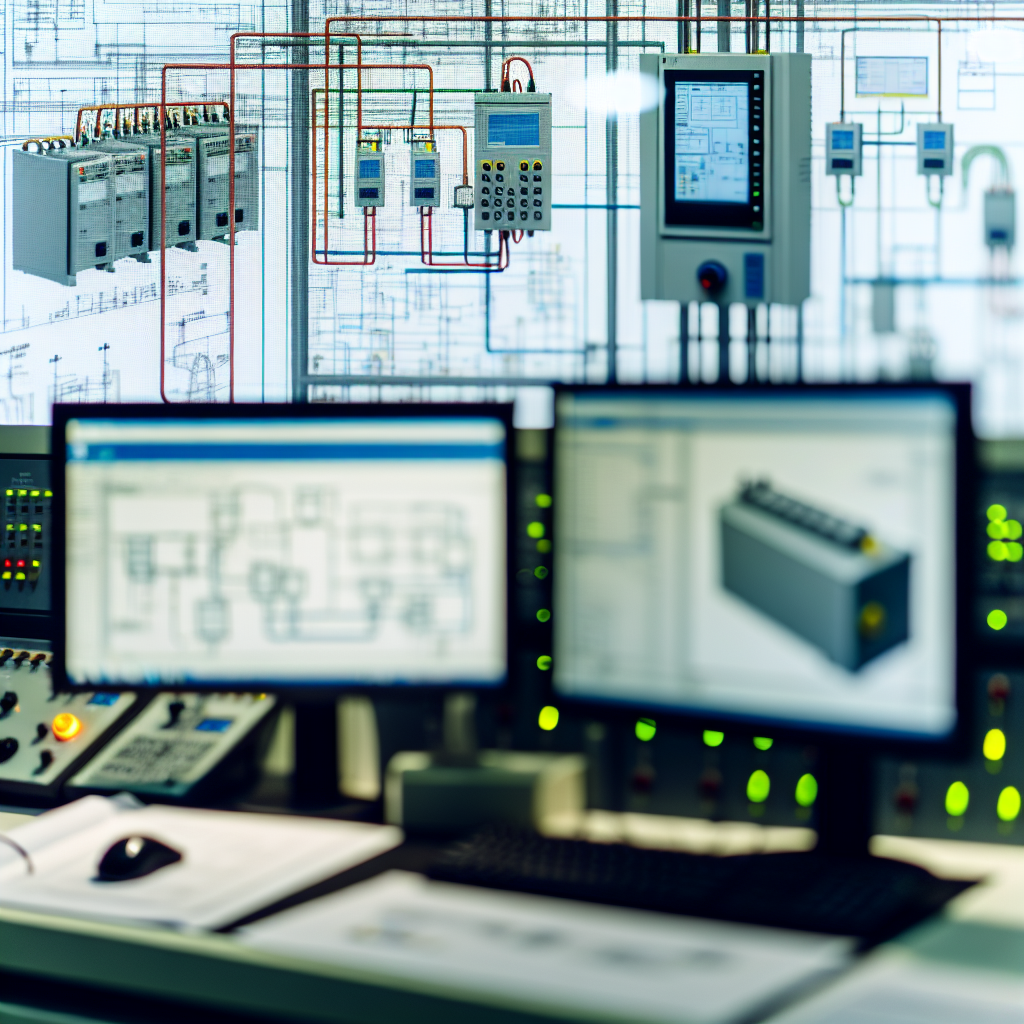

Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) systems are vital components in modern electrical automation. They enable efficient control, monitoring, and data management in industrial environments. This article explores the fundamentals of PLC programming and SCADA systems, highlighting their importance for reliable electrical operations.

Understanding PLC Programming and Its Role in Electrical Automation

**Programmable Logic Controllers (PLCs)** are specialized digital computers designed for industrial automation. They are responsible for executing control algorithms that manage machinery and processes. The core of PLC functionality lies in *PLC programming*—the process of developing logical instructions that determine how a machine responds to various inputs and conditions.

PLC programming involves creating **ladder logic diagrams**, function block diagrams, or structured text that controls devices like motors, sensors, and switches. This code is embedded within the PLC, which then interprets these instructions in real time. Effective PLC programming ensures seamless operation, safety, and efficiency in electrical systems.

In practical applications, PLCs are interconnected with **electrical systems**, enabling automation of tasks such as conveyor belt operation, lighting control, and HVAC management. Advanced PLCs offer features like remote diagnostics, data logging, and integration with other automation systems, making them indispensable in modern electrical infrastructure.

The Integration of SCADA Systems in Electrical Control Environments

**SCADA systems** extend the capabilities of PLCs by providing centralized **supervisory control**, **data acquisition**, and **real-time monitoring** of electrical processes. They gather information from multiple PLCs across facilities, presenting operators with user-friendly dashboards and alarms for quick decision-making.

The effectiveness of a **SCADA system** depends on proficient *scada programming*, which involves configuring data points, alarms, historical logging, and visualization screens. This allows engineers to track system performance, troubleshoot issues, and optimize operations proactively.

By integrating **SCADA systems** with PLCs, organizations benefit from increased visibility into electrical systems, reduced downtime, and improved maintenance practices. Furthermore, SCADA enhances safety by alerting operators to abnormal conditions, preventing catastrophic failures in electrical infrastructure.

Conclusion

Mastering **PLC programming** and **SCADA systems** is essential for advancing electrical automation and ensuring reliable system operation. Understanding how PLC logic integrates with SCADA enables efficient control, real-time monitoring, and effective troubleshooting. Implementing these technologies optimally can significantly improve productivity and safety in electrical environments. Embracing modern automation tools is key to staying ahead in today’s industrial landscape.