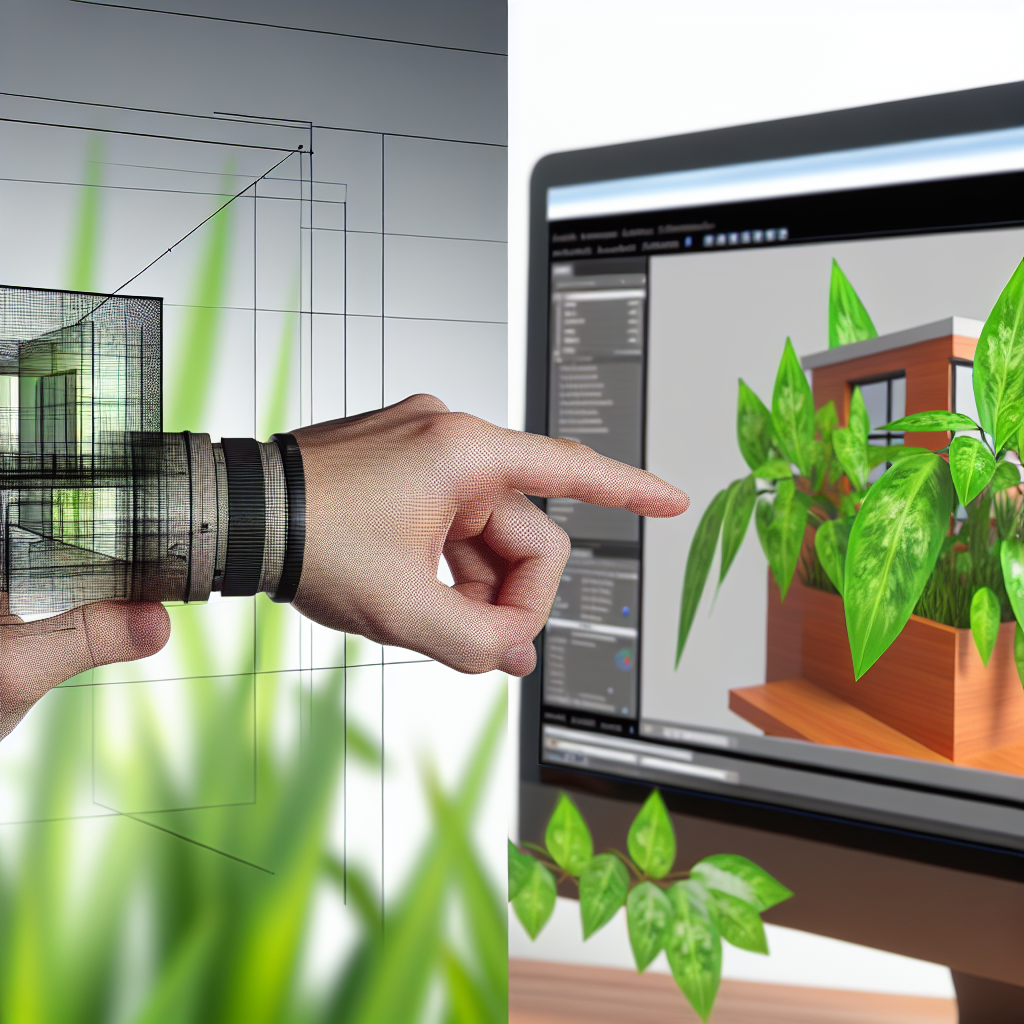

Integrating Revit and Plant 3D enhances multidisciplinary project workflows by combining architectural precision with detailed piping and instrumentation design. This seamless collaboration streamlines project management, reduces errors, and accelerates delivery timelines. Let’s explore how these two powerful tools can work together effectively to elevate engineering and construction projects.

Enhancing Design Integration and Data Compatibility

One of the primary benefits of combining Revit and Plant 3D is improved design integration. Revit, a Building Information Modeling (BIM) tool, excels at architectural and structural modeling, offering detailed 3D visualizations and accurate spatial data. Plant 3D focuses on the detailed design of piping, equipment, and instrumentation within industrial plants.

To achieve effective collaboration, data compatibility between these platforms is critical. Autodesk’s Dynamo scripts, third-party plugins, or direct data export/import features enable the transfer of models and specifications from Revit to Plant 3D and vice versa. This integration ensures consistency in design, prevents clashes, and provides a comprehensive view of the project from architectural to process engineering perspectives.

In practice, designers export models from Revit in formats like IFC or DWG, and then import these into Plant 3D, maintaining orientation, scale, and spatial relationships. This interoperability reduces rework, avoids clashes during construction, and facilitates coordinated revisions across disciplines.

Streamlining Collaboration and Project Management

Beyond data exchange, effective collaboration between Revit and Plant 3D involves synchronization of work processes. Modern workflows often incorporate cloud-based platforms such as Autodesk BIM 360, which enable multiple teams to access, review, and modify models in real-time. This collaborative environment enhances communication, minimizes misunderstandings, and accelerates project timelines.

Using integrated models, teams can perform clash detection and resolving conflicts early in the design phase, saving costs and avoiding delays during construction. Additionally, parametric modeling capabilities in Revit can be linked with the detailed piping layouts in Plant 3D for dynamic updates—any change in architectural or structural design automatically propagates through to process systems, ensuring synchronization across disciplines.

Furthermore, establishing clear standards and protocols for data exchange is essential, including naming conventions, modeling standards, and version controls. Leveraging Autodesk’s native tools and customization options allows teams to automate routines, maintain data integrity, and support complex multi-disciplinary projects seamlessly.

Conclusion

Combining Revit and Plant 3D creates a powerful synergy that enhances project accuracy, reduces errors, and optimizes collaboration across disciplines. By focusing on data compatibility and streamlined communication, teams can deliver comprehensive, clash-free designs efficiently. Embracing this integrated approach offers a competitive edge in the architectural, engineering, and construction industries, ensuring successful project outcomes.