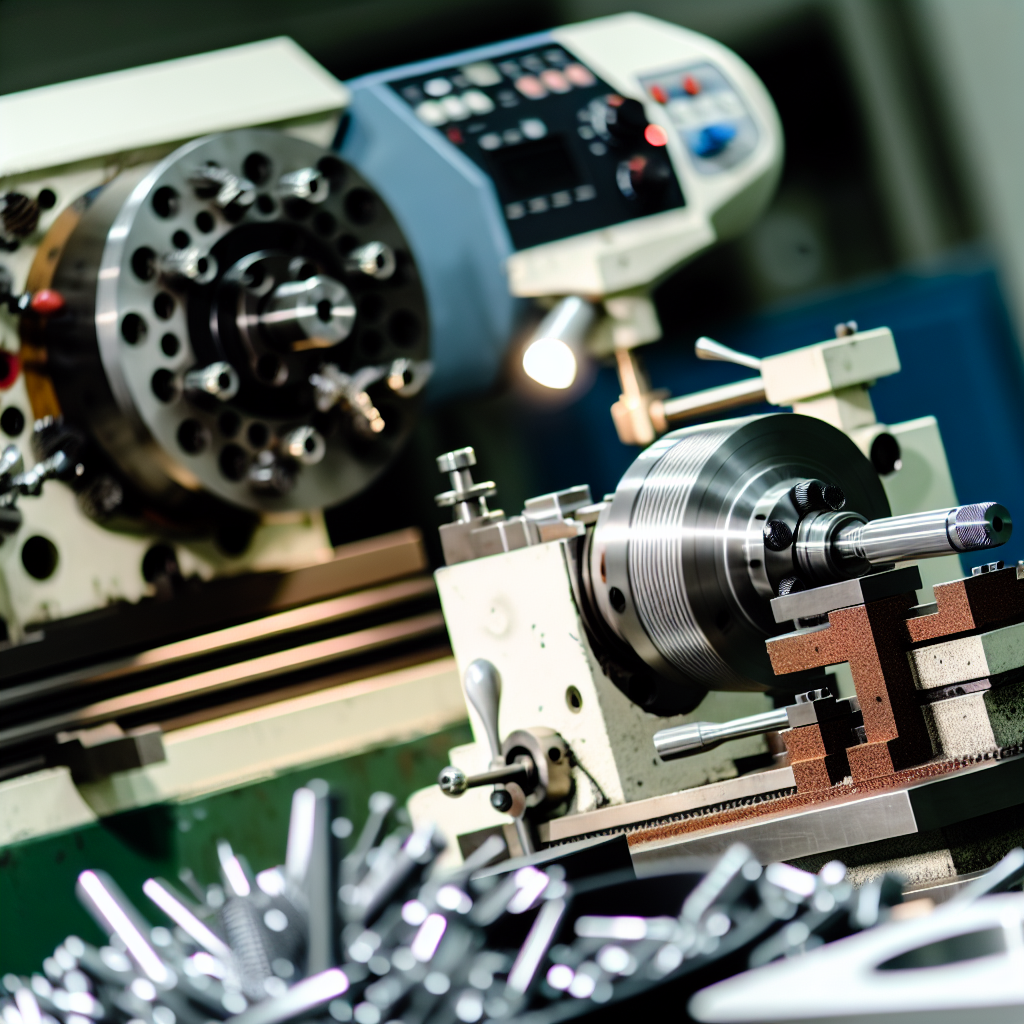

The lathe is a fundamental machine in the realm of mechanical engineering and manufacturing. Its versatility allows for precise shaping, cutting, and finishing of a wide variety of materials, making it an essential tool in workshops and factories worldwide. Understanding the workings and types of lathes can significantly enhance machining efficiency and product quality.

Understanding the Function and Types of Lathes

A lathe primarily functions by rotating a workpiece against a stationary cutting tool, enabling operations such as cutting, sanding, knurling, drilling, or deformation. This rotation allows for the creation of symmetrical objects like cylinders, cones, or spheres with high precision. There are several types of lathes designed to meet specific manufacturing needs, including:

- Engine Lathe: The most common type used for general-purpose machining, suitable for a variety of operations on metal and other materials.

- Turret Lathe: Equipped with a rotating turret holding multiple tools, ideal for producing large numbers of identical parts with automation.

- CNC Lathe: Computer Numerical Control (CNC) lathes automate the machining process, allowing for complex designs with minimal manual intervention, increasing accuracy and repeatability.

Understanding the distinctions among these lathe types is crucial for selecting the right machine based on production volume, complexity, and precision requirements. The choice of lathe also influences the tooling, speed, and feed rates, which directly affect the quality of the finished part.

The Importance of Lathe Maintenance and Mechanical Precision

Maintaining a lathe in optimal condition is vital for ensuring precision, safety, and longevity of the machine. Regular lubrication of moving parts such as ways, lead screws, and bearings reduces wear and tear, leading to more accurate cuts and extended equipment lifespan. Mechanical accuracy depends on several factors, including:

- Alignment: Proper alignment of the headstock, tailstock, and bed ensures concentricity and reduces vibration.

- Calibration: Routine calibration of controls and measurement tools helps maintain dimensional accuracy of machined parts.

- Tool condition: Sharp, well-maintained cutting tools are essential for quality finishes and preventing damage to the workpiece or machine.

Advanced lathes also feature digital readouts and automated systems that assist in maintaining tight tolerances, making modern mechanical lathe operation both efficient and highly precise. Emphasizing regular maintenance and mechanical diligence ensures that the lathe continues to produce quality components reliably over time.

In conclusion, the lathe stands as an indispensable machine in mechanical manufacturing, enabling the creation of complex, symmetrical parts. From understanding the different types of lathes to prioritizing maintenance and mechanical precision, mastering these aspects enhances productivity and product quality. Proper selection and upkeep of lathes empower machinists to achieve outstanding results in their projects.