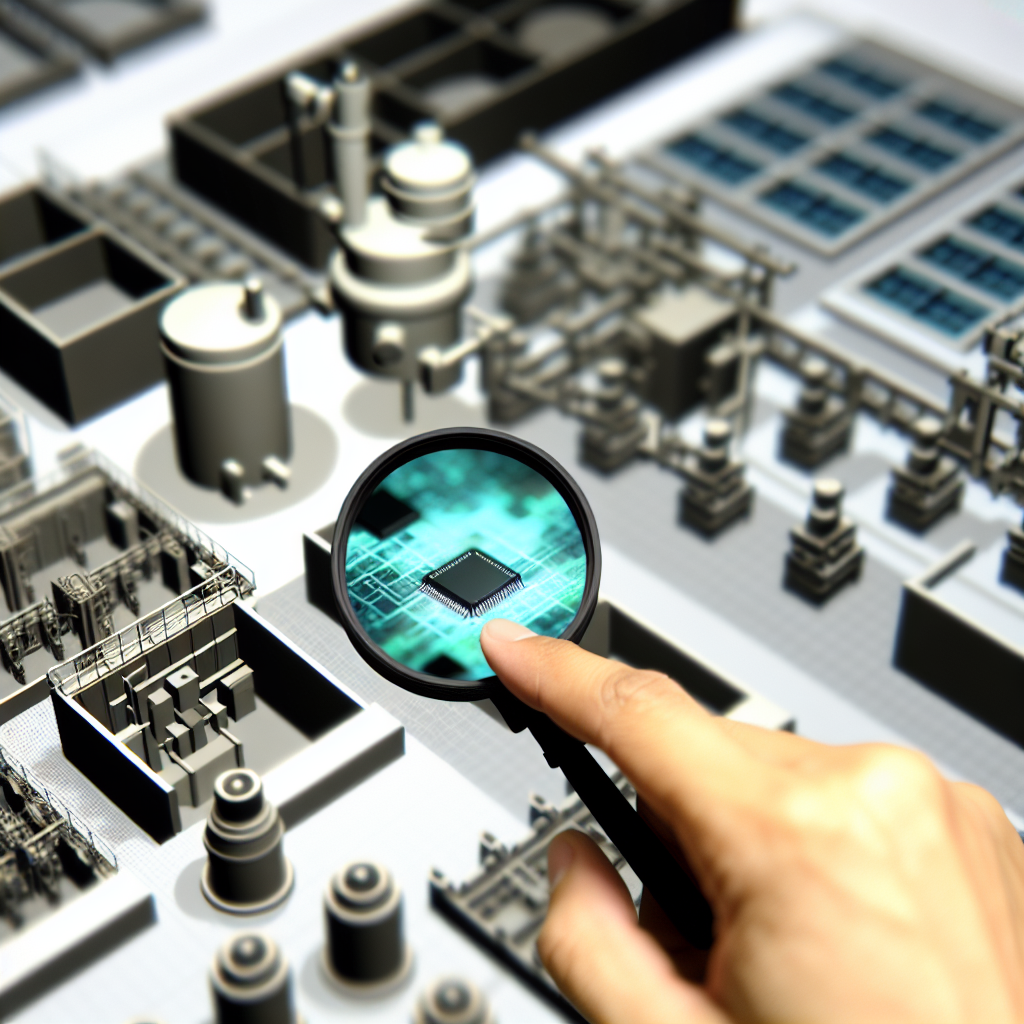

Semiconductor manufacturing is a complex, highly precise process that forms the backbone of modern electronics. Understanding this intricate process is essential to appreciate how tiny chips power everyday devices. In this article, we delve into the detailed steps of semiconductor manufacturing and explore the innovative efforts by industry leaders like Samsung Semiconductor.

Fundamentals of the Semiconductor Manufacturing Process

The process of creating a semiconductor involves multiple stages that require immaculate precision and cleanroom environments to prevent contamination. It all begins with the purification of raw silicon, which is the primary material for most semiconductors. This silicon is refined into highly pure, crystalline forms through processes like the Czochralski method, producing a cylindrical silicon ingot known as a boule.

Once the silicon boule is ready, it is sliced into thin wafers, typically 300mm in diameter. These wafers serve as the foundational platform for building integrated circuits. The manufacturing process then shifts to complex steps such as photolithography, doping, etching, and deposition. Each of these steps involves precise control and technology to define the tiny features that constitute the semiconductor’s active components.

Key Steps in Semiconductor Fabrication

- Photolithography: This is the process of transferring circuit patterns onto the wafer surface using light-sensitive photoresists. High-resolution steppers or scanners project the circuit images onto the wafer, creating the intricate geometries necessary for transistors and interconnects.

- Doping: To modify the electrical properties of silicon, dopants such as boron or phosphorus are introduced into the silicon lattice through processes like ion implantation or diffusion. This step forms p-type and n-type regions essential for transistor function.

- Etching and Deposition: These processes create the layered structures within the chip. Deposition techniques like Chemical Vapor Deposition (CVD) deposit thin films of materials, while etching removes unwanted layers, shaping the microscopic components with high precision.

Throughout these stages, semiconductor manufacturers employ advanced equipment and stringent protocols to ensure quality and yield. The integration of automation, nanotechnology, and innovative materials accelerates progress toward smaller, faster, and more energy-efficient chips.

Conclusion

The semiconductor manufacturing process is a sophisticated blend of chemistry, physics, and engineering, involving meticulous steps from silicon purification to complex patterning and doping. Companies like Samsung Semiconductor continue to push technological boundaries to produce the miniaturized, high-performance chips driving today’s digital world. By understanding these processes, consumers can better appreciate the ingenuity behind modern electronics.